Estimated reading time: 1 minute

Table of contents

- Laying the Foundation for a Profitable Cannabis Facility in New York

- Key Components of a New York Cannabis Facility

- Infrastructure Considerations for a New York Cannabis Facility

- Site-Specific Considerations for New York Cannabis Facilities

- Speed-to-Market: The Competitive Edge

- Verifying Eligibility of a Cannabis Facility Site in New York with ZoLa

- Future-Proofing Your New York Cannabis Facility

- Common Pitfalls in New York Cannabis Facility Design

- Final Thoughts on New York Cannabis Facility Design

- New York Cannabis Facility Design FAQs

- Additional Resources

- Free eBooks For Cannabis Business Success

- Latest Articles

Cliff Notes: New York Cannabis Facility Design

Objective: Developing a New York cannabis facility design requires strategic planning to ensure efficiency, scalability, and full compliance with state regulations. From optimizing workflow to integrating advanced environmental control systems, facility design plays a crucial role in the long-term success of cannabis businesses.

Key Considerations:

- Regulatory Compliance – Adhering to New York cannabis facility compliance requirements, including security measures, zoning laws, and environmental impact.

- Space Optimization – Maximizing high-cost real estate with multi-tiered growing systems and modular layouts.

- Scalability – Designing facilities with future expansion in mind, including oversized electrical and plumbing infrastructure.

- Environmental Controls – Implementing HVAC, lighting, and CO₂ systems tailored to New York’s diverse climate.

- Security & Accessibility – Ensuring controlled entry, 24/7 surveillance, and seamless workflow for staff and operations.

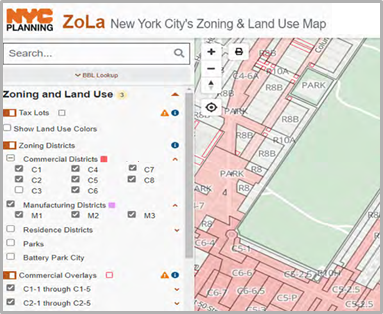

- Identifying the right location is essential for compliance and efficiency. ZoLa (NYC’s Zoning & Land Use Map) helps determine permitted zoning districts, ensuring cannabis businesses operate within regulatory guidelines.

Avoiding Common Pitfalls:

- Underestimating space & infrastructure needs

- Overlooking environmental & security systems

- Poor facility layout leading to inefficiencies

Partner with Catalyst BC to ensure your New York cannabis facility is strategically designed for operational efficiency, compliance, and future scalability. Our team offers expert guidance in layout planning, regulatory alignment, and infrastructure development to set your business up for long-term success. Contact us today for a Complimentary Consultation.

Laying the Foundation for a Profitable Cannabis Facility in New York

Developing a New York cannabis facility design requires more than just constructing a building—it demands strategic planning to optimize efficiency, ensure compliance, and support scalability. Given New York’s evolving cannabis regulations, a well-planned facility can streamline operations and set the stage for long-term success. Many operators have found that working with a New York Cannabis Consultant provides invaluable guidance during the planning phase.

Similar to food processing plants, cannabis cultivation facilities must be designed for workflow efficiency, regulatory adherence, and future expansion to remain competitive in the market. Engaging with experienced professionals through New York Cannabis Consulting can help ensure that every detail is addressed.

Critical Factors in New York Cannabis Facility Design

When designing a New York cannabis cultivation facility, consider these key elements:

- Workflow Optimization – The facility layout should facilitate the seamless movement of plants, staff, and materials. Dedicated pathways, well-placed workstations, and efficient access points improve overall productivity.

- Space Maximization – Given the high cost of real estate in New York, maximizing space is crucial. Utilizing multi-tiered growing systems and modular layouts ensures efficient space use and adaptability for future needs.

- Scalability – The ability to expand operations is vital. Even if starting with a small cultivation area, infrastructure should be designed to support increased capacity over time.

- Regulatory Compliance – New York’s cannabis laws impose strict regulations on facility security, zoning, and environmental impact. Designing with compliance in mind prevents costly retrofits and legal issues.

- Accessibility – Every area of the facility should be easily reachable for maintenance, harvesting, and cleaning. Proper spacing between plants and equipment ensures efficient workflow and reduces labor costs.

Key Components of a New York Cannabis Facility

Indoor Cultivation Rooms

The cultivation area is the heart of any New York cannabis facility design, directly influencing product quality and yield. Key considerations include:

- Size and Layout – A commercial grow room should have a minimum ceiling height of 6-8 feet. Space allocation should be approximately 1-2 sq ft per plant in the vegetative stage and 2-4 sq ft per plant in the flowering stage.

- Environmental Controls – Cannabis thrives under specific conditions:

- Temperature: 70-85°F (21-29°C) during light periods; 62-72°F (17-22°C) during dark periods.

- Humidity: 60-70% for seedlings/clones; 50-60% for vegetative growth; 40-50% for flowering.

- CO₂ Levels: 1,000-1,500 ppm during light periods for maximum photosynthesis.

- Air Circulation & Odor Control – Install inline fans to exchange air 3-5 times per hour. New York’s strict odor regulations require carbon filters rated at 200-400 CFM per 1,000 watts of lighting to minimize environmental impact.

Expert New York Cannabis Consulting can help you design the cultivation rooms to precisely meet these requirements.

Support Rooms and Processing Areas

To maintain compliance and product quality, New York cannabis facilities require designated spaces for post-harvest processes:

- Drying Room – Maintain 60-70°F with 45-55% humidity for 4-10 days to properly cure cannabis.

- Curing Area – Store cannabis in a dark space at 60-70°F with 55-65% humidity for 2-8 weeks to enhance potency and flavor.

- Packaging Room – A clean and controlled environment with proper ventilation ensures product safety and compliance with New York’s packaging and labeling laws.

- Storage Areas – Keep nutrients in climate-controlled storage (50-70°F) and harvested cannabis at 60-70°F with 55-62% relative humidity to preserve quality.

Environmental Control Systems

- HVAC Systems – New York’s climate varies greatly, requiring efficient heating and cooling systems. Install an HVAC system capable of handling 25-35 BTU per square foot of grow space.

- Lighting – LED bulbs with 2.0-2.8 μmol/J efficacy provide the best energy efficiency and growth customization.

- Automated Monitoring – Integrated sensor networks track temperature, humidity, CO₂ levels, pH, and EC levels with real-time alerts and data logging to meet regulatory standards.

Many facility owners consult with New York Cannabis Consulting experts to ensure that environmental systems are designed for both efficiency and compliance.

Infrastructure Considerations for a New York Cannabis Facility

Designing a Reliable & Scalable Cannabis Facility in New York

To operate efficiently and remain compliant, your New York cannabis facility design must include robust infrastructure:

- Electrical & Water Supply – Cannabis cultivation requires significant power loads for lighting, HVAC, and irrigation. Electrical infrastructure must handle peak loads, while water systems should include filtration and recirculation to minimize waste. For precise planning, consider engaging a New York Cannabis Consultant.

- Security & Compliance – New York’s cannabis laws mandate strict security measures, including:

- Controlled entry systems and restricted access areas.

- 24/7 video surveillance covering all facility zones.

- Regulatory compliance with state cannabis cultivation and processing laws to avoid legal risks.

- Workflow Efficiency – Design facility layouts for logical movement through different growth and processing stages, ensuring accessibility for trimming, packaging, and maintenance.

Site-Specific Considerations for New York Cannabis Facilities

The location of your cannabis facility impacts its design in several ways:

- Climate Considerations – New York experiences hot summers and cold winters, requiring well-designed HVAC and insulation systems to maintain optimal growing conditions.

- Zoning & Building Codes – Regulations vary by city and county. Working with a New York Cannabis Consultant can ensure compliance with New York State cannabis licensing requirements.

- Electrical Supply – Choose a site with sufficient power capacity to support commercial cannabis operations.

- Logistics & Accessibility – Easy access to suppliers, distributors, and transportation hubs improves efficiency and product distribution.

Speed-to-Market: The Competitive Edge

The cannabis industry is highly competitive, making speed-to-market essential. Many owners rely on investors rather than traditional financing, so getting a facility operational quickly can make or break success.

- Phased Construction: Accelerates production timelines.

- Early Engagement: Involving design teams early ensures efficient facility planning.

- Pre-Approved Sites: Prevent delays caused by zoning or power supply issues.

Strategic advice from a New York Cannabis Consultant can be invaluable in shortening the time-to-market.

Verifying Eligibility of a Cannabis Facility Site in New York with ZoLa

To locate a new proposed business on a property in New York City, first establish what Use Group the activity fits within the NYC Zoning Resolution, then match that Use Group to the permitted zoning districts. The locations of the zoning districts where use is permitted can be identified by using NYC’s Zoning & Land Use Map (ZoLa).

For example, a Conditional Adult-Use Retail Dispensary (CAURD) cannabis business is considered Use Group VI. Use Group VI is permitted in all commercial zoning districts (except C3) and in M1, M2, and M3 Manufacturing districts. Other cannabis business types, their Use Groups and the districts in which they are permitted are shown in the tables:

| STATE LICENSE TYPE | USE GROUP1 (PRE-ZEO UG): USE NAME (NAICS CODE) | PERMITTED IN DISTRICTS | NOTES |

| Adult-Use Retail Dispensary | UG VI (6C): Miscellaneous Retailers (4599) | C1 – C8 except C3 M1 M2 M3 | As-of-Right |

| Adult-Use Retail Dispensary with Temporary Delivery-Only Location | UG IX(A) (7B, 16D): Micro-distribution facility, warehouse | C1, C2 | Up to 2,500 sf; outside Manhattan, not permitted in C1-1 through C1-4 and C2- 1 through C2-4 |

| C4 – C7 | Up to 5,000 sf at ground floor; 10,000 sf above ground floor | ||

| C8 | As-of-Right | ||

| M1 – M3 | Conform to performance standards | ||

| Adult-Use Processor | UG X (6A, 17B): Food manufacturing (311), Beverage and tobacco product manufacturing (312) | C1, C2 | Limited to 5,000 sf in C1 and C2 except 3,000 sf in C1-1 through C1-4 |

| C4-C7 | Limited to 10,000 sf at ground floor; limitless area above ground floor | ||

| C8 M1 – M3 | No limitation in floor area |

| STATE LICENSE TYPE | USE GROUP1 (PRE-ZEO UG): USE NAME (NAICS CODE) | PERMITTED IN DISTRICTS | NOTES |

| Adult-Use Distributor | UG IX(A) (7C, 11B, 16D): micro-distribution facility, wholesale establishment, warehouse | C1, C2 | Limited to 2,500 sf; outside Manhattan, not permitted in C1-1 thru C 1-4 and C2-1 thru C2-4 |

| C4-C7 | Up to 5,000 sf at ground floor; 10,000 sf above ground floor | ||

| C8 Ml – M3 | No limitation in floor area | ||

| Adult-Use Cultivator | UG I (4B, 17C): Agricultural uses, including greenhouses, nurseries, or truck gardens | R1- R1O | No offensive odors or dust created; limited to greenhouses |

| C1, C2 | No offensive odors or dust created; limited to greenhouses | ||

| C3-C8 | No offensive odors or dust created; indoor and greenhouses permitted | ||

| M1 – M3 | Conform to performance standards; indoor and greenhouses permitted |

Using ZoLa, the geographic locations of the Zoning Districts where Use Group VI businesses are permitted can be determined. Once in ZoLa, under Zoning Districts in the legend on the left, specific districts can be selected to display. Expand the Zoning District categories and select the applicable commercial and manufacturing districts.

ZoLa can also be used to search for a particular address, or block and lot, to learn the Zoning Regulations that apply to the particular property. When viewing a property on ZoLa, it is also possible to access the official zoning map that applies to the property by using a link on the right-side panel.

Future-Proofing Your New York Cannabis Facility

Scalability & Expansion Planning

As the cannabis market in New York continues to grow, designing a facility with future expansion in mind is essential.

- Modular Design – Implement flexible layouts that allow for easy repurposing or expansion of cultivation areas.

- Oversized Infrastructure – Invest in high-capacity electrical and plumbing systems that can support future growth.

- Flexible Equipment – Choose automation and scalable processing systems that adapt as production demands increase.

Key considerations for long-term success include:

- Space – Allocate room for additional grow rooms and processing areas.

- Power & Water – Ensure infrastructure can handle future demand.

- Waste Management – Plan for scalable waste disposal systems to meet environmental regulations.

Common Pitfalls in New York Cannabis Facility Design

Underestimating Space & Infrastructure Needs

Many new cannabis operators miscalculate spatial requirements, leading to inefficiencies and overcrowding. Touring existing New York cannabis facilities can provide insights into actual space needs.

Overlooking Critical Systems

- Environmental Controls – Precise management of temperature, humidity, and air circulation is essential for plant health and compliance.

- Security Measures – Robust security protects against theft and regulatory penalties.

- Workflow Efficiency – Poor layouts lead to higher labor costs and reduced productivity.

Final Thoughts on New York Cannabis Facility Design

A successful New York cannabis facility design requires careful planning, regulatory compliance, and a focus on efficiency. From initial construction to daily operations, every aspect should be optimized for productivity, sustainability, and long-term growth.

Since cannabis facility development is highly regulated in New York, our team of New York Cannabis Consulting experts will help navigate zoning laws, licensing requirements, and infrastructure needs. Contact us today for a Complimentary Consultation.

Your cannabis facility is more than just a growing space—it’s the foundation of your business. Designing for efficiency, compliance, and future expansion will position your operation for sustained success in the competitive New York cannabis market.

New York Cannabis Facility Design FAQs

A successful design must prioritize regulatory compliance, security, workflow efficiency, environmental controls, and scalability. Consulting with a New York Cannabis Consultant can provide valuable insights.

Zoning laws dictate where cultivation and processing facilities can operate, with specific restrictions varying by city and county. A New York Cannabis Consultant can help interpret these laws.

A cultivation room should allocate at least 1-2 sq ft per plant in the vegetative stage and 2-4 sq ft in the flowering stage, ensuring efficient airflow and maintenance access.

A cannabis facility in New York needs an HVAC system that maintains 70-85°F with humidity control and air exchange rates optimized for plant health and compliance.

Workflow efficiency can be improved by designing clear pathways, strategic workstation placement, and dedicated spaces for cultivation, processing, and packaging.

Security requirements include controlled entry, 24/7 surveillance, restricted access zones, and compliance with state regulations. Expert guidance from New York Cannabis Consulting experts is often essential.

Yes, working with experienced professionals ensures compliance with New York’s strict cannabis laws and helps design an efficient, scalable facility. Contact our New York Cannabis Facility Design Consulting Team to receive a complimentary consultation.

LED grow lights with high efficacy (2.0-2.8 μmol/J) are ideal for New York cannabis cultivation, ensuring energy efficiency and optimal plant growth.

Cannabis facilities require high-capacity electrical systems for lighting and HVAC, along with water filtration and recirculation systems to minimize waste.

Drying rooms should maintain 60-70°F with 45-55% humidity, while curing areas should be kept in a dark space at 60-70°F with 55-65% humidity for optimal potency.

Using modular design, oversized infrastructure, and scalable equipment ensures that a facility can expand as business demand grows.

Risks include non-compliance with zoning laws, inadequate security, and poor environmental controls. A New York Cannabis Consultant can identify and mitigate these risks.

Carbon filtration systems rated at 200-400 CFM per 1,000 watts of lighting help control odors and comply with state environmental regulations.

Energy efficiency can be improved by using LED lighting, optimizing HVAC systems, and implementing automated environmental controls.

A well-designed facility layout enhances workflow efficiency, reduces labor costs, and ensures seamless plant movement from cultivation to processing.

Additional Resources

Free eBooks For Cannabis Business Success

Latest Articles

- Utah Medical Cannabis Pharmacy License Applications Open for 2025: Eligibility, Deadlines, and RequirementsThe Utah Department of Agriculture and Food (UDAF) has officially launched the first application period for two independent medical cannabis pharmacy licenses, running from July 1 through July 31, 2025. Originating from House Bill 54, passed during Utah’s 2025 legislative session, these new pharmacy licenses aim to broaden medical cannabis access in medically underserved areas across the state.

- Cannabis Startup Costs: From Licensing to ProfitabilityStarting a legal cannabis business isn’t just about getting a license—it’s about building a profitable, compliant, and sustainable operation in one of the world’s most capital-intensive and regulated industries. Many entrepreneurs enter this space with many goals, good intentions, and passion, but ultimately fail because they underestimate the cost, complexity, experience, and time required to turn a cannabis license into a thriving business.

- Cannabis License Pitfalls: How to Avoid Common Cannabis Licensing MistakesAs new adult-use programs launch, many entrepreneurs are eager to start growing, processing, or selling cannabis. Excitement runs high, but the industry’s heavy regulations and complex operations can quickly overwhelm even experienced business owners. Common mistakes include underestimating compliance requirements, rushing facility design, skipping proper procedures, and more.

- Maximizing Your Minnesota Cannabis Microbusiness or Mezzobusiness LicenseMinnesota’s new adult-use cannabis law allows microbusinesses (one store, up to 5,000 sq ft indoor, ½ acre outdoor) and mezzobusinesses (up to 3 stores, 15,000 sq ft indoor, 1 acre outdoor) to cultivate, manufacture, sell, and transport cannabis under one license. These vertically integrated licenses offer flexibility, but also come with complex state rules.

- The Recipe for a Top-Tier Cannabis DispensaryOperating a highly reviewed, top-performing cannabis dispensary takes more than simply stocking product and unlocking the doors. It requires operational discipline, regulatory expertise, top-tier customer service, dynamic merchandising, and a culture of accountability and community. With the cannabis industry continuing to expand—and regulations constantly evolving—success is defined by how seamlessly a dispensary integrates compliance, product curation, staff training, and marketing into day-to-day operations.

- Minnesota Lottery Results: June 5 Cannabis License Drawings and What’s NextThe Minnesota Lottery for cannabis business licenses reached a pivotal milestone on June 5, as the Office of Cannabis Management (OCM) conducted randomized drawings for select license types. These lotteries were open to both social equity applicants and general applicants vying for limited licenses to operate as cultivators, manufacturers, and mezzobusinesses. Additionally, a separate lottery was held exclusively for social equity applicants seeking a retail cannabis license.