Estimated reading time: 1 minute

Table of contents

- Editor’s Note

- The Growing Demand for Cannabis Facilities

- Why Controlled Environments Matter

- Key Areas in a Cannabis Grow Facility

- Critical Infrastructure Considerations

- Site Selection and Pre-Planning

- Speed-to-Market: The Competitive Edge

- Final Thoughts on Cannabis Facility Design

- Cannabis Grow Facility Design FAQs

- Additional Resources

- Free eBooks For Cannabis Business Success

- Latest Articles

Cliff Notes: Essential Considerations for Cannabis Grow Facility Design

Objective: Designing a high-performing cannabis cultivation facility requires a strategic approach that balances compliance, sustainability, and operational efficiency to meet growing industry demand and ensure long-term profitability.

Key Components:

- Cannabis Industry Growth: Legalization has made cannabis one of the top U.S. crops, surpassing $6B in wholesale value and increasing the demand for efficient facility design.

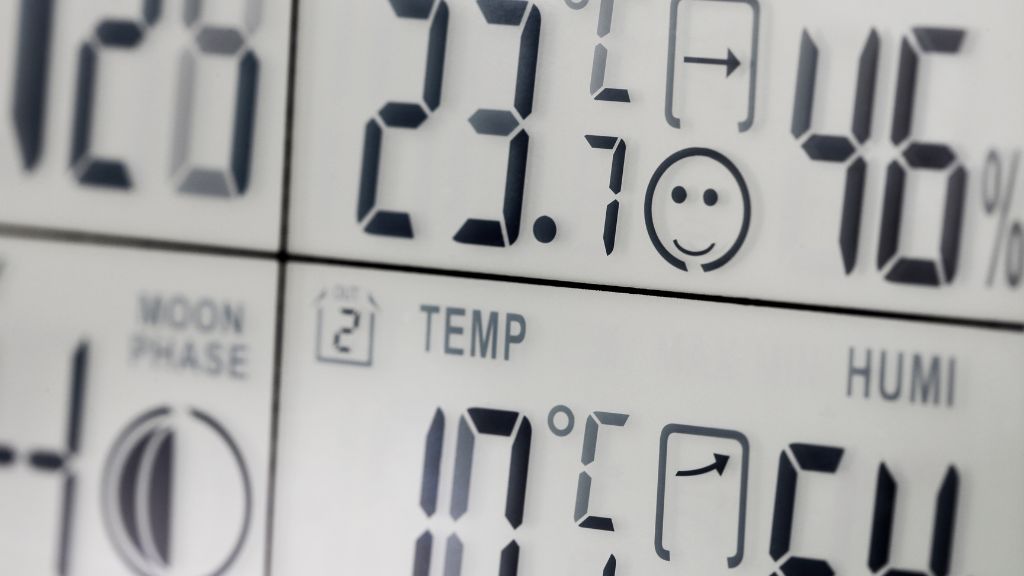

- Importance of Controlled Environments: Stable climate control through HVACD ensures high-quality yields, supports continuous production, and enhances compliance with CO₂ and air quality regulations.

- Facility Zoning: Key grow areas like mother, clone, veg, and flower rooms require specific environmental controls, along with dedicated processing and compliance zones.

- HVACD & Airflow Systems: Proper air movement, dehumidification, and contamination prevention are central to facility efficiency and plant health.

- Water & Nutrient Management: Automated fertigation and water reclamation systems improve sustainability and operational control.

- Lighting & Energy Efficiency: LED lighting solutions help reduce energy consumption while meeting compliance requirements.

- Strategic Planning: Site selection, power access, zoning, and phased construction are critical for fast-tracking operations and achieving long-term facility success.

Partner with Catalyst BC to streamline your cannabis facility design—our expert consultants help you navigate compliance, optimize infrastructure, and accelerate speed-to-market with scalable, future-proof solutions. Contact us for a Complimentary Consultation.

Editor’s Note

This article is part one of the Cannabis Facility Design Essentials series. Find the additional parts below:

1. Cannabis Grow Facility Design: Essential Considerations for Success

2. Demystifying HVACD Systems for Cannabis Grow Facilities

3. Optimizing Water Use in Cannabis Grow Facility Design

4. Cannabis Facility Design Safety: Creating Compliant Environments

The Growing Demand for Cannabis Facilities

The cannabis industry continues to flourish, with adult-use cannabis ranking as one of the most valuable crops in the United States. According to Cannabis Business Times, the wholesale harvest value of adult-use cannabis exceeded $6 billion in 2020, making it the fifth most valuable crop behind corn, soybeans, hay, and wheat.

As more states legalize cannabis for medical and recreational use, the demand for high-quality cannabis grow facility design will only increase. Cultivation and manufacturing facilities must be designed with precision to optimize yields, ensure compliance, and create a sustainable and profitable operation. Many companies now turn to Cannabis Consulting services for expert guidance on designing and building these facilities.

Why Controlled Environments Matter

Cannabis cultivation is most successful in controlled environments, such as greenhouses or fully indoor grow operations. These Controlled Environment Agriculture (CEA) facilities offer several advantages, including:

- Consistent environmental control – Optimized temperature, humidity, lighting, water, and airflow ensure maximum yield and product quality.

- Year-round production – Indoor facilities allow for continuous harvest cycles, independent of outdoor weather conditions.

- Pest and contamination prevention – Isolation from mold, insects, pollen, and other contaminants improves product safety and quality.

- Odor control – Proper ventilation systems mitigate strong odors associated with cannabis cultivation.

- Security and compliance – Restricted access ensures compliance with state regulations.

- Reduced transportation needs – On-site processing and packaging minimize the need for external distribution.

Most cannabis grow facility designs follow a vertically integrated model, where cultivation, processing, manufacturing, quality control, and packaging are managed under one roof. Cultivators often engage a Cannabis Consultant to help implement these controlled systems effectively, ensuring that each facility component contributes to overall operational success.

Key Areas in a Cannabis Grow Facility

A well-designed cannabis facility includes specialized grow rooms, each catering to different growth stages. These rooms must have precisely controlled conditions to maximize plant health and efficiency.

Mother Room

- Houses mature plants used to propagate clones.

- Requires 70°F to 85°F and 40% to 55% relative humidity (RH).

- Lighting runs 18+ hours per day to prevent flowering.

- Typically occupies 5% of the total cultivation space.

Many facility designers collaborate with a Cannabis Consultant to determine the optimal size and configuration for the mother room.

Clone Room

- Small plant cuttings develop roots before transplanting to the vegetative stage.

- Maintained at 60°F to 80°F and 50% to 70% RH.

- Lighting is 18 to 24 hours per day to encourage root growth.

Vegetative (Veg) Room

- Plants grow larger in preparation for flowering.

- Requires 70°F to 85°F and 50% to 65% RH.

- Lighting remains on 18 hours per day.

- Typically takes up 20% of total cultivation space.

Flower Room

- The final stage before harvest, where plants develop buds.

- Kept at 72°F to 85°F and 45% to 60% RH.

- Lighting cycles shift to 12 hours on / 12 hours off to trigger flowering.

- Represents 70% of the total cultivation area.

Additional Facility Spaces

Aside from grow rooms, cannabis grow facilities require additional spaces for processing, compliance, and operations:

- Irrigation and water treatment rooms – Store and manage fertigation systems.

- Trimming and drying rooms – Prepare harvested cannabis for packaging.

- Extraction and lab spaces – Used for processing concentrates and testing product quality.

- Packaging and storage areas – Secure spaces for product preparation and distribution.

- Security and compliance zones – Restricted-access areas to comply with state regulations.

An experienced cannabis consulting team can help plan these supplementary areas to ensure seamless operations across the entire facility.

Critical Infrastructure Considerations

HVACD (Heating, Ventilation, Air Conditioning, and Dehumidification)

Proper HVACD design is essential for controlling environmental conditions, ensuring airflow distribution, and preventing microclimates that could lead to mold or disease.

- 100% air recirculation minimizes contamination.

- Year-round cooling and dehumidification ensure stable conditions.

- CO₂ enrichment optimizes photosynthesis.

- Filtration and disinfection prevent airborne contaminants.

Experienced professionals, including a Cannabis Consultant, are often brought in by companies to optimize their HVACD systems for maximum efficiency.

Water and Nutrient Management

Efficient fertigation (nutrient-infused irrigation) is key to successful cultivation.

- Reverse osmosis (RO) water is stored and mixed with nutrients before delivery to plants.

- Automated controls regulate daily watering schedules.

- Water reclamation systems recycle excess irrigation water (leachate) to improve efficiency.

Lighting and Energy Requirements

Lighting plays a crucial role in cannabis grow facility design, with many jurisdictions mandating energy-efficient options.

- LED or high-intensity discharge (HID) lights are commonly used.

- Some states require low-power density lighting or restrict non-LED options.

- Facilities must ensure adequate electrical capacity, as cultivation areas may require 80 watts per square foot.

Partnering with a Cannabis Consultant with expertise in energy management can lead to significant operational savings and compliance with state mandates.

Security and Compliance Features

- Access control systems restrict unauthorized entry.

- CO₂ monitoring and emergency ventilation ensure worker safety.

- Fire protection systems meet local building codes and safety regulations.

Site Selection and Pre-Planning

Choosing the right location for a cannabis grow facility is crucial to long-term success. Key factors to consider include:

- Adequate power supply – Facilities require high electricity loads for lighting and HVACD.

- Local zoning and compliance – Some municipalities have specific cannabis cultivation restrictions.

- Room for expansion – Future facility scaling should be factored into site selection.

- Mechanical and electrical infrastructure – Sufficient space for equipment placement and utility connections.

Many investors seek advice from Cannabis Consulting experts to identify optimal sites that balance regulatory compliance and expansion potential.

Speed-to-Market: The Competitive Edge

The cannabis industry is highly competitive, making speed-to-market essential. Many owners rely on investors rather than traditional financing, so getting a facility operational quickly can make or break success.

- Phased construction can accelerate production timelines.

- Early engagement with design teams ensures efficient facility planning.

- Pre-approved sites prevent delays caused by zoning or power supply issues.

Final Thoughts on Cannabis Facility Design

Building a successful cannabis grow facility requires a deep understanding of environmental control, infrastructure planning, and regulatory compliance. By carefully designing each element—from HVACD systems to lighting, fertigation, and security—cultivators can maximize efficiency, maintain product quality, and stay ahead in a rapidly evolving industry.

Partner with Catalyst BC to streamline your cannabis facility design—our expert consultants help you navigate compliance, optimize infrastructure, and accelerate speed-to-market with scalable, future-proof solutions. Contact us for a Complimentary Consultation.

Cannabis Grow Facility Design FAQs

Cannabis grow facility design must include proper HVACD, irrigation, lighting, security, and compliance features to ensure an efficient, compliant, and high-yield operation. Working with a Cannabis Consultant can help refine these aspects.

HVACD systems regulate temperature, humidity, airflow, and CO₂ levels, ensuring a stable environment for plant health and preventing mold, pests, and diseases.

Cannabis HVACD systems are designed for high humidity loads, 24/7 operation, and CO₂ enrichment, unlike standard HVAC systems that lack precise environmental control.

Temperature and humidity vary by growth stage. Veg rooms require 70-85°F with 50-65% RH, while flower rooms need 72-85°F with 45-60% RH. Expert Cannabis Consultants can help optimize these parameters.

Controlled environments allow year-round production, optimize yields, prevent contamination, and maintain compliance. A Cannabis Consultant often recommends these setups.

CO₂ enrichment increases photosynthesis efficiency, leading to faster plant growth and higher yields in indoor cannabis cultivation facilities.

LED and HID lights are commonly used. LEDs offer energy efficiency, while HID lights provide high-intensity output but require more cooling. Many businesses turn to Cannabis Consultants for advice on lighting solutions.

HVACD systems with energy recovery, geothermal cooling, and automation help reduce power consumption and improve sustainability.

Cannabis facilities must have access control, surveillance, CO₂ monitoring, and fire suppression systems to meet regulatory standards.

Carbon filters, air scrubbers, and negative pressure rooms help manage odor emissions to comply with local regulations.

Proper airflow prevents stagnant zones, enhances transpiration, and reduces mold risks by maintaining uniform temperature and humidity.

Factors like power supply, zoning laws, and expansion potential influence facility efficiency, compliance, and long-term viability. Many investors consult with Cannabis Consulting experts during site selection.

Speed-to-market refers to how quickly a cannabis facility can start operations, impacting revenue potential and investor confidence.

Greenhouses utilize natural sunlight with supplemental HVACD, while indoor facilities rely entirely on artificial lighting and climate control.

Efficient fertigation systems optimize plant growth by delivering precise nutrient levels while reducing water waste through reclamation systems.

Additional Resources

Free eBooks For Cannabis Business Success

Latest Articles

- Missouri Cannabis Licensing & Business Opportunities 2026Missouri has established itself as the premier success story for cannabis in the Midwest, evolving from a standard medical regime to a high-volume adult-use market that exceeded $1.52 billion in annual sales in 2025. As the market enters the 2026–2027 biennium, the landscape is shifting from rapid expansion toward operational maturation and specialized entry.

- North Carolina Cannabis Licensing & Business Opportunities 2026North Carolina remains one of the final significant jurisdictions in the United States without a comprehensive medical or adult-use cannabis program. However, the 2026–2027 biennium is projected to be the most consequential period in the state’s cannabis history. Driven by the formation of the North Carolina Advisory Council on Cannabis and an impending federal “hemp cliff,” the state is moving from a period of passive prohibition toward a structured, albeit highly restrictive, regulatory framework.

- Nebraska Cannabis Licensing & Business Opportunities 2026Nebraska is entering the 2026–2027 biennium at a historic crossroads. Following the 71% voter approval of Initiatives 437 and 438 in late 2024—the largest margin for a medical cannabis initiative in U.S. history—the state is currently standing up its first regulated medical infrastructure.

- Florida Cannabis Licensing & Business Opportunities 2026Florida represents the most capital-intensive and professionally structured cannabis market in the nation. As of 2026, the state is at a crossroads: it is both expanding its mature medical program and preparing for a potential constitutional shift toward universal adult-use access. On November 3, 2026, Florida voters will decide on the Marijuana Legalization Initiative (Amendment 3). Passing this requires a 60% supermajority—a high threshold, but one that polls suggest is within reach.

- Virginia Cannabis Licensing & Business Opportunities 2026As Virginia transitions from its current “possession-only” model toward a fully regulated retail market, the 2026–2027 biennium represents a once-in-a-generation window for market entry. Unlike the vertically integrated “medical-only” regimes of the past, Virginia’s upcoming framework focuses on decentralization, specifically architected to favor small Virginia-based operators over large multi-state corporations.

- Minnesota Cannabis Licensing & Business Opportunities 2026Minnesota is currently undergoing a transformative shift in its cannabis landscape, moving from a semi-regulated hemp-derived market toward a fully comprehensive adult-use framework. Overseen by the Office of Cannabis Management (OCM), the 2026–2027 biennium represents the critical “enforcement phase” where temporary registrations sunset and permanent, merit-based licenses define the market’s long-term leaders.