Estimated reading time: 13 minutes

Table of contents

- Overview of Class Action Lawsuit Against Valley Crest Farms

- The Landmark Legal Ruling: Setting a Precedent in Cannabis Litigation

- Why Cannabis Cultivators Must Prioritize Environmental Control

- Advanced Environmental Control Technology for Cannabis Cultivation

- The Importance of Professional Guidance in Environmental Control Technology

- Conclusion: The Future of Odor Control in the Cannabis Industry

- Cannabis Odor Control FAQs

- Additional Resources

- Free eBooks For Cannabis Business Success

- Latest Articles

Cliff Notes: How Cultivators Can Prevent Legal Issues with Advanced Solutions

Objective: Avoid the same legal and operational implications of the Valley Crest Farms class-action lawsuit, emphasizing the growing need for effective odor control in cannabis cultivation through advanced environmental control technologies and expert consulting.

Key Components:

- Landmark Lawsuit: A California judge has allowed a class-action lawsuit to proceed against Valley Crest Farms over cannabis odors, potentially impacting up to 100 homes near the facility.

- Resident Complaints: Plaintiffs allege that strong, persistent cannabis smells have harmed property values, rental income, and overall quality of life.

- Legal Precedent: This is the first class-action suit in California tied to cannabis odor, setting a significant precedent for future environmental claims.

- Odor Control Imperative: The lawsuit highlights the critical need for proactive odor mitigation strategies in cannabis operations—especially near residential areas.

- Technology Solutions: Effective methods include carbon filtration, HEPA filters, negative air pressure systems, photocatalytic oxidation, ozone generators, and biofiltration.

- Expert Guidance Matters: Engaging Cannabis Consultants ensures regulatory compliance, custom mitigation strategies, community goodwill, and cost savings.

- Industry Wake-Up Call: As cannabis markets mature, operators must prioritize environmental controls not just to meet regulations—but to safeguard their business and reputation.

Partner with Catalyst BC to design and implement advanced odor control solutions tailored to your facility’s needs. Our team of expert Cannabis Consultants will help you stay compliant, avoid costly setbacks, and build a cultivation operation that earns community trust. Book a Complimentary Consultation.

Overview of Class Action Lawsuit Against Valley Crest Farms

A recent California Superior Court ruling has sent ripples through the cannabis industry by allowing a class-action lawsuit to proceed against Valley Crest Farms, a greenhouse cannabis cultivation operation in Carpinteria Valley. The case revolves around persistent odor complaints from nearby residents, who claim that the strong, unpleasant smell of cannabis has negatively impacted their property values, businesses, and overall quality of life.

Beyond its legal significance, this lawsuit underscores a critical issue within the cannabis industry: the need for advanced environmental control technology (ECT) in cultivation facilities. With the increasing legalization of cannabis across the U.S., growers must prioritize odor mitigation strategies to comply with regulations, avoid litigation, and maintain positive community relations. This article explores the lawsuit’s implications, the role of controlled environment agriculture (CEA) in cannabis cultivation, and the importance of professional guidance in implementing cutting-edge odor control systems. Many growers have found that working with a Cannabis Consultant can help implement cutting-edge odor control solutions. Additionally, engaging Cannabis Consulting services has become a key strategy for those seeking to prevent legal issues related to odor.

The Landmark Legal Ruling: Setting a Precedent in Cannabis Litigation

Superior Court Judge Thomas Anderle ruled in favor of the Santa Barbara Coalition for Responsible Cannabis, certifying the class action lawsuit against Valley Crest Farms. This decision allows residents within a one-mile radius of the farm to seek damages for odor-related disturbances. Many industry experts, including those from Cannabis Consulting firms, view this ruling as a turning point for addressing odor issues in cannabis operations.

Key Details of the Ruling

- Class Action Eligibility: Homeowners within one mile of the greenhouse operation who purchased their properties before January 19, 2016, qualify for the lawsuit.

- Claim Requirements: Plaintiffs must demonstrate that cannabis odor has negatively affected their property values, rental potential, business revenue, or enjoyment of their property.

- Potential Impact: This case could affect up to 100 homes in the designated radius and establish new legal precedents for odor-related complaints against cannabis operations.

The plaintiffs argue that the “sewer-like” smell emanating from Valley Crest Farms has resulted in financial and emotional distress. In legal filings, they claim that tenants have moved out due to the unbearable odor, business income has declined, and homeowners have been unable to sell their properties at fair market value. Many legal teams advising cultivators now recommend proactive measures through Cannabis Consulting to avoid similar disputes.

This ruling marks the first class-action lawsuit certification in California related to cannabis odor, setting a powerful precedent that could influence future cases across the state and beyond.

Why Cannabis Cultivators Must Prioritize Environmental Control

As legal cannabis markets mature, environmental management becomes a vital part of compliance and community relations. While cannabis production offers significant economic benefits, odor control remains a persistent challenge for cultivators operating near residential or commercial areas. Experts in Cannabis Consulting stress that effective odor control not only helps maintain regulatory compliance but also preserves a positive brand reputation.

The Science Behind Cannabis Odor

Cannabis plants produce volatile organic compounds (VOCs), including terpenes, which are responsible for the plant’s distinct aroma. Common terpenes that contribute to cannabis odor include:

- Myrcene – Earthy, musky, and clove-like scent.

- Limonene – Citrus-like aroma.

- Pinene – Pine-like fragrance.

While these compounds are harmless, their strong scent can travel significant distances, particularly in greenhouse and outdoor cultivation settings. Without proper odor mitigation technology, the aroma can permeate surrounding neighborhoods, leading to community complaints and potential legal action. Many cultivators now rely on Cannabis Consulting insights to deploy effective odor control measures that minimize these risks.

Legal & Regulatory Consequences of Poor Odor Control

Cannabis businesses that fail to implement effective odor control measures may face:

- Zoning and permitting challenges – Many municipalities require comprehensive odor control plans for licensing approval.

- Fines and regulatory penalties – Non-compliance with local air quality standards can result in hefty fines.

- Lawsuits and legal settlements – As seen in the Valley Crest case, failing to address odor concerns can lead to costly litigation and reputational damage.

Engaging a Cannabis Consultant who specializes in environmental control is often recommended to prevent these legal pitfalls.

Advanced Environmental Control Technology for Cannabis Cultivation

To prevent legal disputes and maintain operational efficiency, controlled environment agriculture (CEA) technology plays a crucial role in odor mitigation. By implementing advanced filtration, air circulation, and climate control systems, cannabis cultivators can drastically reduce odor emissions while optimizing plant health. Many cultivators work with Cannabis Consulting firms to identify the best solutions for their operations.

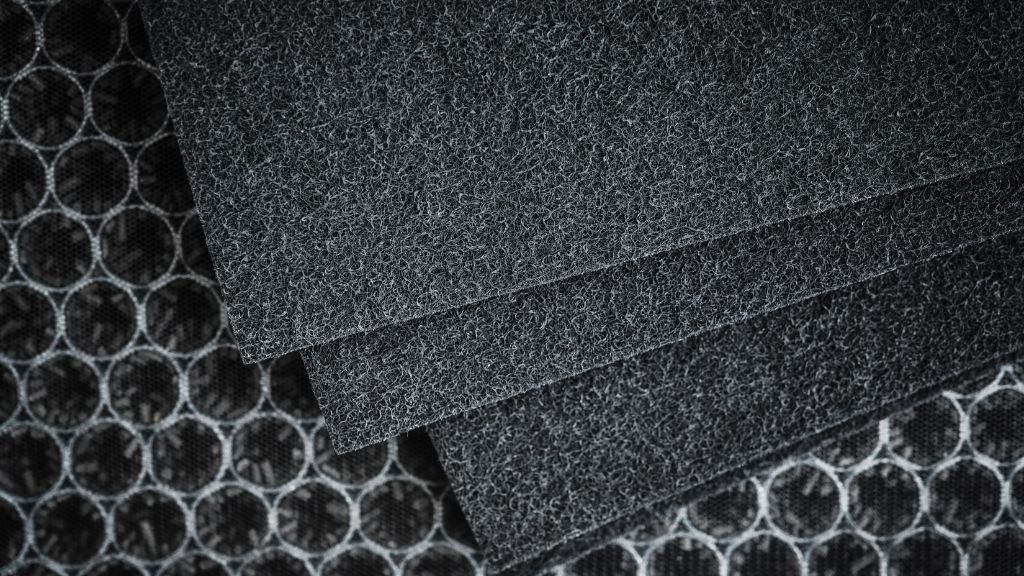

Carbon Filtration Systems (“Scrubbers”)

Carbon filtration is the industry standard for odor control. These systems use activated carbon filters to trap and neutralize odor-causing molecules before they exit the facility.

How Carbon Filtration Works

- Air passes through activated carbon media, which absorbs terpenes and VOCs.

- Clean, odor-free air is then expelled from the facility.

- Regular maintenance ensures long-term efficiency and prevents filter saturation.

High-Efficiency Particulate Air (HEPA) Filtration

HEPA filters are widely used in pharmaceutical and food processing industries to maintain air purity. In cannabis cultivation, HEPA filters can:

- Reduce airborne contaminants, including pollen, mold spores, and dust.

- Improve odor control by capturing fine particulate matter associated with cannabis odor.

Negative Air Pressure & Airflow Management

Maintaining negative air pressure inside a cultivation facility prevents cannabis odor from escaping. This method works by:

- Continuously drawing air into the facility rather than allowing it to escape.

- Directing air through filtration systems before venting outside.

- Reducing odor leakage through doors, windows, and ventilation systems.

Photocatalytic Oxidation (PCO) & Ozone Generators

Some cannabis operations utilize photocatalytic oxidation (PCO) technology or ozone generators to break down odor-causing molecules at a chemical level. These systems:

- Use UV light and titanium dioxide to neutralize VOCs.

- Generate ozone to oxidize odor compounds (note: excessive ozone use can pose health risks).

Biofiltration Systems

Biofiltration is an eco-friendly approach to odor control that uses natural microorganisms to break down terpenes and VOCs in cannabis cultivation. These systems:

- Pass odorous air through a biofilter media (e.g., wood chips, compost).

- Allow microbes to digest odor compounds, effectively neutralizing the smell.

The Importance of Professional Guidance in Environmental Control Technology

Cannabis cultivation is a highly regulated industry, and improper environmental management can lead to costly legal battles, community resistance, and operational inefficiencies. Partnering with environmental control experts is essential for successful odor mitigation. Many businesses find that consulting with a Cannabis Consultant provides critical support in developing and implementing these advanced systems. Whether you work with Cannabis Consulting team or a dedicated Cannabis Consultant, expert guidance can help ensure compliance and long-term operational success.

Why Expert Guidance Matters

- Regulatory Compliance & Licensing Support

- Experts ensure facilities meet local and state air quality regulations.

- Proper odor control plans improve the likelihood of obtaining licensing approvals.

- Customized Odor Mitigation Strategies

- Every facility is unique, requiring tailored solutions for odor control.

- Consultants assess facility design, airflow dynamics, and emission points to optimize odor management.

- Cost Savings & Risk Reduction

- Investing in advanced odor control prevents expensive lawsuits and regulatory fines.

- Proper facility planning reduces the need for costly retrofits down the road.

- Community Relations & Brand Reputation

- Addressing odor concerns proactively fosters positive relationships with local communities.

- A well-maintained facility demonstrates a commitment to responsible and sustainable cannabis cultivation. Many businesses consult a Cannabis Consultant to improve community relations through effective environmental control.

Conclusion: The Future of Odor Control in the Cannabis Industry

The Santa Barbara Coalition for Responsible Cannabis lawsuit against Valley Crest Farms serves as a wake-up call for the cannabis industry. As legal challenges surrounding odor control become more common, businesses must adopt proactive environmental management strategies to avoid similar legal battles.

The future of cannabis cultivation relies on integrating cutting-edge environmental control technology, including carbon filtration, HEPA systems, negative air pressure, and biofiltration. With proper expert guidance and compliance strategies, operators can:

- Ensure long-term operational success.

- Build trust within their communities.

- Avoid regulatory pitfalls and costly legal disputes.

For cannabis businesses, investing in environmental control solutions is not just about compliance—it’s about creating a sustainable, efficient, and legally sound cultivation operation that will stand the test of time.

Partner with Catalyst BC to design and implement advanced odor control solutions tailored to your facility’s needs. Our team of expert Cannabis Consultants will help you stay compliant, avoid costly setbacks, and build a cultivation operation that earns community trust. Book a Complimentary Consultation.

Cannabis Odor Control FAQs

Cannabis plants typically start to emit a noticeable scent during the flowering stage. This is when the plant produces more terpenes and cannabinoids in preparation for bud production. Many growers consult with a Cannabis Consultant to better understand plant development stages.

Cannabis has a strong, distinctive aroma that stems from a blend of volatile organic compounds (VOCs), primarily terpenes and, more recently identified, volatile sulfur compounds (VSCs). Terpenes are well-known VOCs found in many plants, and in cannabis, they create a wide range of scents—from earthy and skunky to citrusy and floral. Common examples include myrcene, which contributes to the classic “skunky” odor; limonene, which adds a citrusy note; and caryophyllene, known for its peppery scent. More recent studies have revealed that volatile sulfur compounds also play a critical role in cannabis’s aroma, particularly in cultivars with especially strong or pungent smells. One compound in particular, 3-methyl-2-butene-1-thiol, has been identified as a major contributor to the skunky scent profile found in some high-odor strains.

Across the spectrum, cannabis aromas are generally defined in three main categories: Sweet at one end of the spectrum (encompassing fruity or tropical notes); Savory at the other (onion, garlic, or chemical); Prototypical aromas in the middle (earthy, spicy, or skunky).

The term ‘gassy’ refers to a pungent, diesel-like smell often associated with powerful and high-quality cannabis strains. The main terpenes that contribute to this distinct aroma are myrcene, limonene, and caryophyllene.

Activated carbon filters remove chlorine, VOCs, and other impurities that affect taste and odor. Cannabis Consulting professionals often recommend carbon filtration as a key component in odor control strategies.

A photocatalysis air purifier is a device that uses photocatalytic oxidation technology to purify indoor air. It uses a photocatalyst and UV light to produce oxidizing agents that can destroy organic pollutants in the air. The purified air is then released back into the room.

An ozone generator produces ozone to oxidize and eliminate odor compounds. While effective, excessive ozone can be harmful, so many growers seek guidance from a Cannabis Consultant to balance its use.

Carbon filters excel at removing gases, odors, and volatile organic compounds (VOCs), while standard filters primarily trap airborne particles like dust and pollen.

Carbon filters are designed to purify both air and water by trapping unwanted substances through a process called adsorption, where molecules cling to the surface of the carbon. In air purification, they are effective at reducing odors from sources like cooking, tobacco, and diesel fumes, and at capturing harmful volatile organic compounds (VOCs). In water, carbon filters help remove chemicals such as chlorine and hydrogen sulfide, as well as heavy metals like lead. Beyond filtration, used carbon can be repurposed as a composting aid, cleaning agent, soil amendment, or for further water treatment.

A HEPA filter removes airborne particles like dust, mold, pollen, and bacteria. HEPA stands for “high efficiency particulate air”. HEPA filters are pleated mechanical filters that are designed to trap at least 99.97% of particles that are 0.3 microns in size or large.

HEPA filters will not remove most viruses, because they are simply too small. HEPA filters will also not remove VOCs, or volatile organic compounds, as they are also too small. Still, HEPA filter technology can be combined with other technologies that will remove these things from your air too.

No. Negative pressure helps contain odors within a facility, preventing them from leaking outside. This technique, recommended by many Cannabis Consultants, is crucial for odor mitigation.

Photocatalytic oxidation is the process of destroying organic substances by oxidation. The technology is well suited to remove low concentrations pollutants (ppb level) from water, air and surfaces.

In many cases biofiltration is both the least expensive and most effective treatment option, which has led to its widespread use. A biofilter uses moist organic materials to adsorb and then biologically degrade odorous compounds.

Odor control systems include chemical adsorption, biological oxidation, chemical scrubbing, and combined technologies. A Cannabis Consultant can help determine the most suitable system for your facility.

Additional Resources

Free eBooks For Cannabis Business Success

Latest Articles

- Missouri Cannabis Licensing & Business Opportunities 2026Missouri has established itself as the premier success story for cannabis in the Midwest, evolving from a standard medical regime to a high-volume adult-use market that exceeded $1.52 billion in annual sales in 2025. As the market enters the 2026–2027 biennium, the landscape is shifting from rapid expansion toward operational maturation and specialized entry.

- North Carolina Cannabis Licensing & Business Opportunities 2026North Carolina remains one of the final significant jurisdictions in the United States without a comprehensive medical or adult-use cannabis program. However, the 2026–2027 biennium is projected to be the most consequential period in the state’s cannabis history. Driven by the formation of the North Carolina Advisory Council on Cannabis and an impending federal “hemp cliff,” the state is moving from a period of passive prohibition toward a structured, albeit highly restrictive, regulatory framework.

- Nebraska Cannabis Licensing & Business Opportunities 2026Nebraska is entering the 2026–2027 biennium at a historic crossroads. Following the 71% voter approval of Initiatives 437 and 438 in late 2024—the largest margin for a medical cannabis initiative in U.S. history—the state is currently standing up its first regulated medical infrastructure.

- Florida Cannabis Licensing & Business Opportunities 2026Florida represents the most capital-intensive and professionally structured cannabis market in the nation. As of 2026, the state is at a crossroads: it is both expanding its mature medical program and preparing for a potential constitutional shift toward universal adult-use access. On November 3, 2026, Florida voters will decide on the Marijuana Legalization Initiative (Amendment 3). Passing this requires a 60% supermajority—a high threshold, but one that polls suggest is within reach.

- Virginia Cannabis Licensing & Business Opportunities 2026As Virginia transitions from its current “possession-only” model toward a fully regulated retail market, the 2026–2027 biennium represents a once-in-a-generation window for market entry. Unlike the vertically integrated “medical-only” regimes of the past, Virginia’s upcoming framework focuses on decentralization, specifically architected to favor small Virginia-based operators over large multi-state corporations.

- Minnesota Cannabis Licensing & Business Opportunities 2026Minnesota is currently undergoing a transformative shift in its cannabis landscape, moving from a semi-regulated hemp-derived market toward a fully comprehensive adult-use framework. Overseen by the Office of Cannabis Management (OCM), the 2026–2027 biennium represents the critical “enforcement phase” where temporary registrations sunset and permanent, merit-based licenses define the market’s long-term leaders.